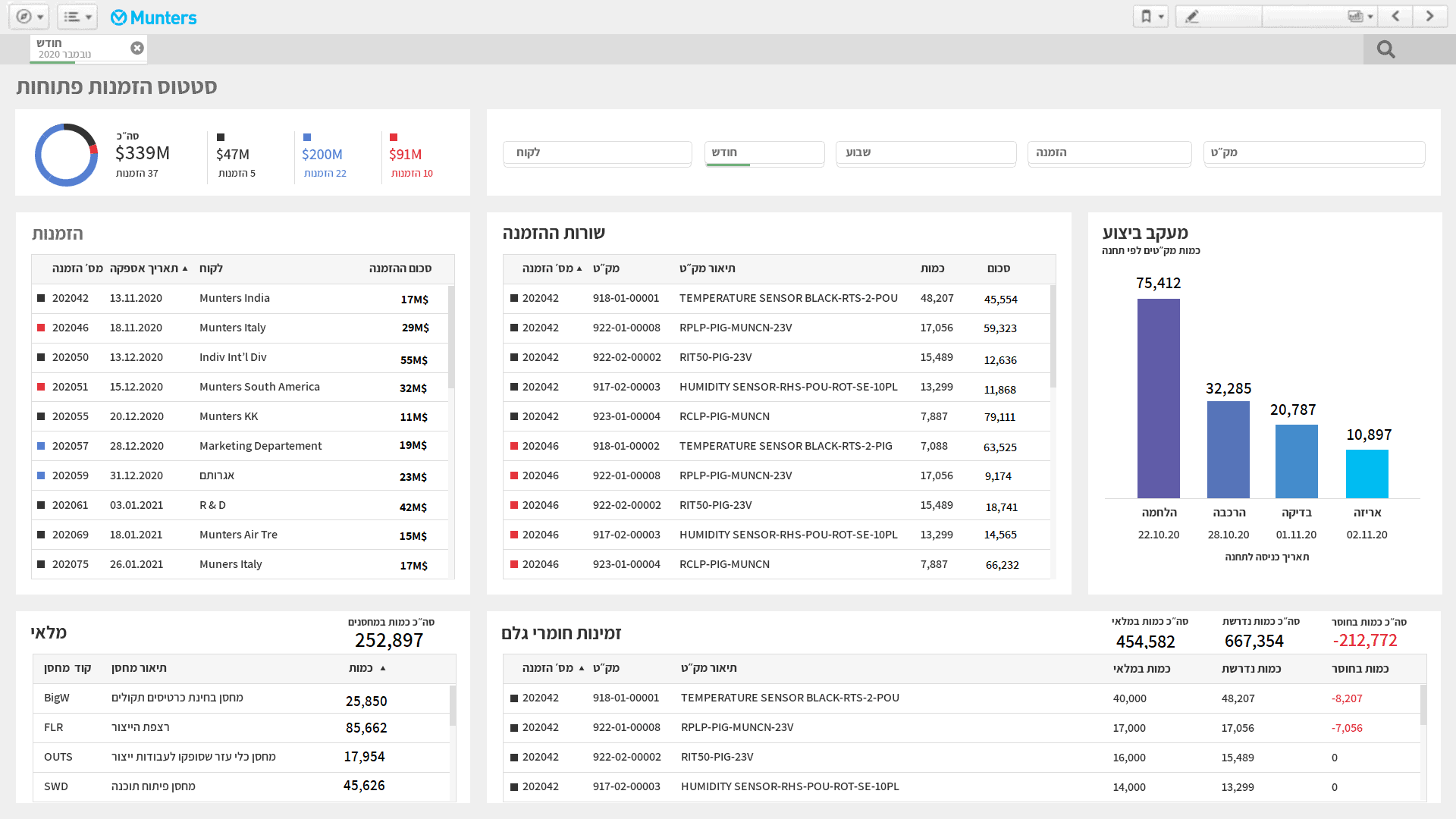

Prior to the project, when the production manager was asked to directly identify the abnormal orders, he was able to locate and handle them only after manual and straining work in Priority.

In the framework of the project, the organization was able to receive a complete picture of the entire ordering system, including irregular orders, according to a variety of sections and plates, all in one screen in a user-friendly interface.

Also, the production manager was now allowed for the first time to move from the BI system directly to the specific order line in Priority after identifying an irregular order and handling it. As a result of the process, the work of the production manager has been significantly streamlined and so has the productivity of the organization.

* The information presented does not reflect the organization’s actual data and is for illustration purposes only.